Explomin seeks mineral wealth to bring it to the surface, day by day they face the challenge of exploring the depths of our soils, in search of minerals.

Diamond drilling is done by using a diamond drill bit to drill the rock/ ground obtaining a core of it, which is extracted, registered and placed in core boxes for proper protection and storage at the client coreshack. Diamond bits are used for drilling since diamond is the existing material with the highest hardness and thermal conductivity on the planet, which allows it to act as a cutting tool with great effectiveness to cut the rock and conveniently extract the core samples of the mineralized deposit.

Diamond drilling can be used at a very early stage (Greenfield project) to target mineralized bodies, determine if mineralization is deepening, verify grades, and determine mineralized resources within a deposit or mining project. In the same way, it can also be used in a later stage (Brownfield) to expand existing reserves, or it can be drilling in the mine that serves as control drilling (for production) or confirmatory drilling in the deepening of the interior of the mine to cubic new mineral reserves.

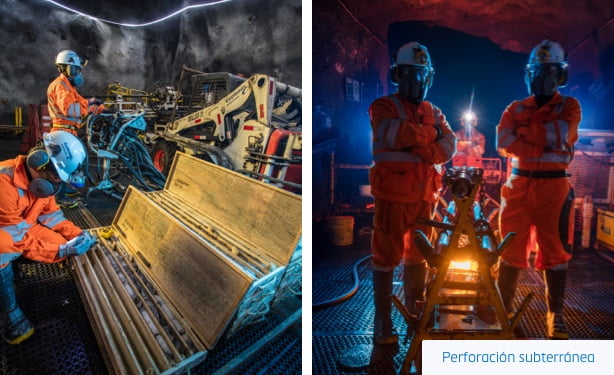

At EXPLOMIN we have modern drilling machinery for surface and underground mines that can go up to 2,000 meters deep. In addition to the highly trained and experienced personnel that allows us to provide the highest drilling performance in the market, by optimizing the service and providing savings for the CLIENT.

We have Rod handling systems for both surface and underground mines that allow a safer operation since it minimizes the exposure of our personnel when handling rods to drill.